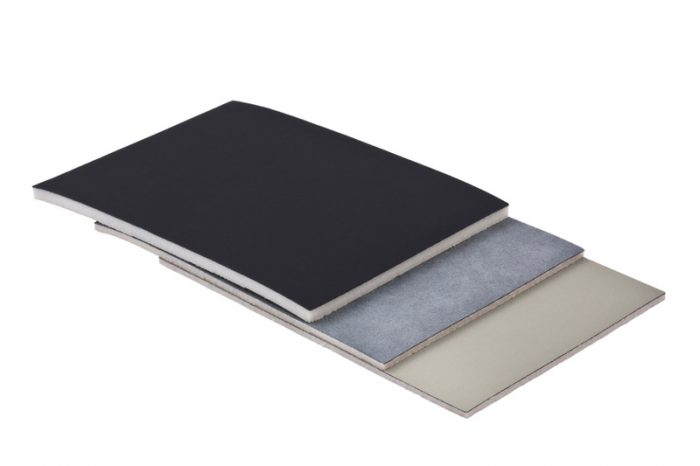

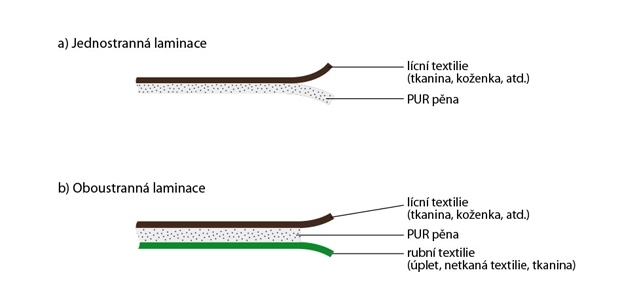

Výroba vrstvených materiálů v metráži, jejichž součástí je vrstva PU pěny. PU pěna je natavena plamenem, a následně mezi válci linky slepena s dalším substrátem. Tavenina pěny plní funkci lepidla. Průchod linkou umožňuje oboustranné vrstvení současně.

Výstupem vrstvený materiál s tloušťkou vrstvy PU pěny do 40 mm, maximální pracovní šíře stroje 2 000 mm.

![[:en]Flame lamination 1[:]](https://www.tomatex.cz/wp-content/uploads/2017/07/laminoplamen1-700x467.jpg)

![[:en]Flame lamination 2 tomatex[:]](https://www.tomatex.cz/wp-content/uploads/2020/06/laminace_n1-700x442.jpg)

![[:en]Flame lamination 3[:]](https://www.tomatex.cz/wp-content/uploads/2020/04/plamen.png)

![[:en]Powder lamination 3[:]](https://www.tomatex.cz/wp-content/uploads/2017/07/laminoplamen2-700x467.jpg)

![[:en]Flame lamination 5[:]](https://www.tomatex.cz/wp-content/uploads/2020/06/plamenna-laminace-4-700x467.jpg)

![[:en]Flame lamination 6[:]](https://www.tomatex.cz/wp-content/uploads/2017/07/plamenna-laminace-6-700x467.jpg)